Laboratory operation and maintenance

Expanding the operation and maintenance service of science and technology laboratory focuses on providing all-round and high quality operation and maintenance guarantee for scientific research institutions, universities and enterprise laboratories. We have an experienced and skilled team committed to ensuring the stable operation and efficient use of the laboratory through advanced technical means and professional service concepts.

Scientific research backing service accompanying

high level talent team

It has 15 professional operation and maintenance engineers, 10 senior engineers over 10 years, and several after-sales assistants and commissioners. Rich experience in laboratory engineering, for different projects, different design and control principles, make different (according to microbiology, constant temperature and humidity and other overall laboratory design standards) debugging and testing, and issue self-inspection reports and some feasible rectification suggestions.

rapid response mechanism

60 minute response

24 hour door.

3 days to solve the problem

Full service content

Provide a range of services from equipment selection, installation and commissioning, daily maintenance, troubleshooting to technical training to ensure that the laboratory is always in the best condition. At the same time, we also provide regular inspection and preventive maintenance services to effectively prevent potential failures, reduce equipment failure rates, and improve laboratory operating efficiency.

Equipped with professional testing equipment

Our company is equipped with corresponding testing equipment for the comprehensive technical parameters of the laboratory, mainly including anemometer, temperature and humidity meter and noise monitor. During the operation and maintenance of the project, technical parameters such as temperature and humidity, cleanliness, wind speed, air exchange rate and noise in the laboratory shall be tested.

Impact of lack of maintenance

01

Air Conditioning System

1. Dirty blockage of return air filter: low pressure alarm.

2. outdoor dirty consequences: high pressure alarm

3. Wet tank dirty consequences: humidifier alarm.

4. Dirty and blocking consequences of air conditioning water system: normal refrigeration cannot guarantee constant temperature and humidity.

5. Electric heating power reduction consequences: can not guarantee a constant temperature.

6. Do not detect the concentration of antifreeze in the water system in winter: cause the system to freeze.

7. Waterway not cleaning and water consequences: causing water flow failure and water temperature alarm, serious damage to the evaporator

8. The consequences of abnormal operating pressure of the system: the protection of the air-conditioning host cannot guarantee a constant temperature, and the compressor will be burned in serious cases.

02

Ventilation system

1. Consequences of loose fan belt: insufficient fan air volume and belt slippage.

2. Consequences of loose bolts of electrical accessories in the electric box: poor power supply contact and burning of seasonal accessories.

3. Fan fixed parts loose consequences: fan noise.

4. Bearing lack of oil consequences: damage to the bearing and drive shaft.

03

Water supply and drainage, pure water system

1. The consequences of the water pump being blocked by debris: no water, serious burning of the water pump

2. Valve corrosion consequences: water leakage or pipeline blockage.

3. Waterway filter dirty consequences: insufficient water flow.

4 water in the air consequences: water vibration, cavitation, shorten the life of the waterway.

5. Ultra filter replacement consequences: affect water quality.

04

Gas system

1. Valve failure consequences: gas pressure out of control.

2. Consequences of pipeline leakage: Major safety accidents may occur.

3. Pressure gauge failure consequences: gas pressure is not allowed, damage to equipment and even cause safety accidents.

05

Waste Water System

1. Pump failure consequences: wastewater treatment system

Not working.

2. The consequences of dirty blocking system: burn water pump and other related components.

3. Aeration valve damage consequences: the system does not work.

5s management mode

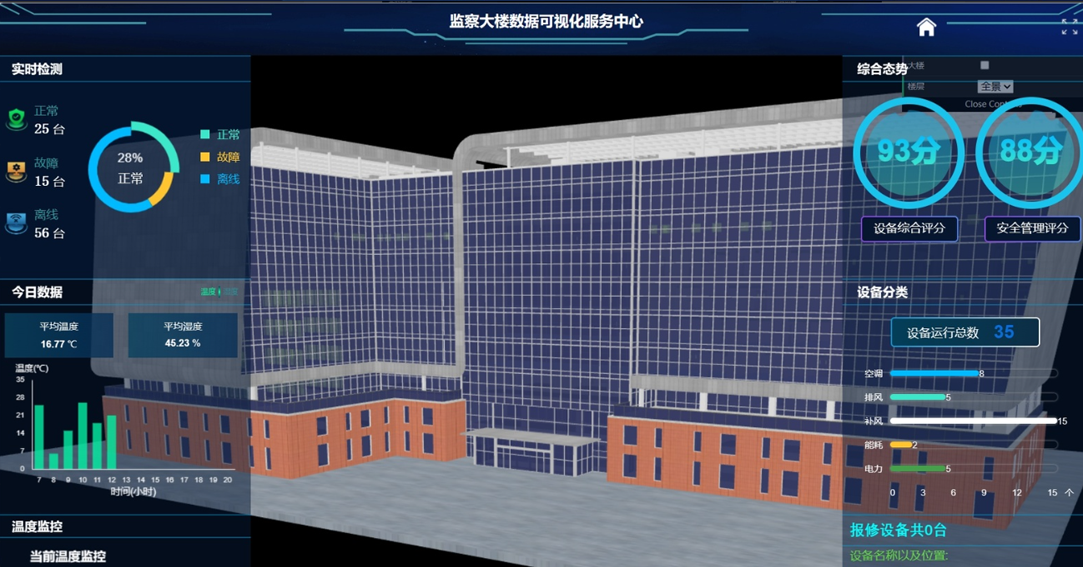

In the maintenance work, 5S management mode is adopted, a perfect maintenance ledger system is established, a perfect spare parts stocking system is possessed, comprehensive intelligent management is implemented, comprehensive big data collection and analysis are carried out on maintenance work orders, spare parts inventory, equipment ledgers, fault records, etc., and maintenance plans and schemes are regularly updated according to the actual situation of the project. Remote real-time monitoring of equipment operating parameters, equipment failure can automatically remote alarm, our company will take the initiative to arrange personnel to contact and deal with after receiving the alarm.

One-stop intelligent operation and maintenance platform

A new generation of laboratory intelligence platform, the intelligence ability comes from the real-time data of the laboratory environment of the whole sample, including environmental data, equipment data, behavior data. A verifiable laboratory business analysis model, and the ability to match the full sample data to obtain acceptable improvement and optimization recommendations under the relevant model.

Intelligent management system

Through preset workflow rules, based on factors such as work order content, urgency, skill matching, etc., the system can intelligently assign tasks to the most suitable service personnel, automatically track the work order status, promote the seamless flow of work orders between various processing links, and reduce redundant links, which ensures the rational use of resources and the smooth and efficient service process.

Remote Equipment Maintenance System

The remote equipment maintenance system realizes the remote monitoring, diagnosis, maintenance and management of the equipment through the Internet of things technology. Operation and maintenance personnel can view the operating status, parameter information, fault records, etc. of the equipment in real time, and make necessary adjustments and maintenance of the equipment through remote operation. This system enables operation and maintenance personnel to monitor and troubleshoot the equipment in real time without visiting the site.

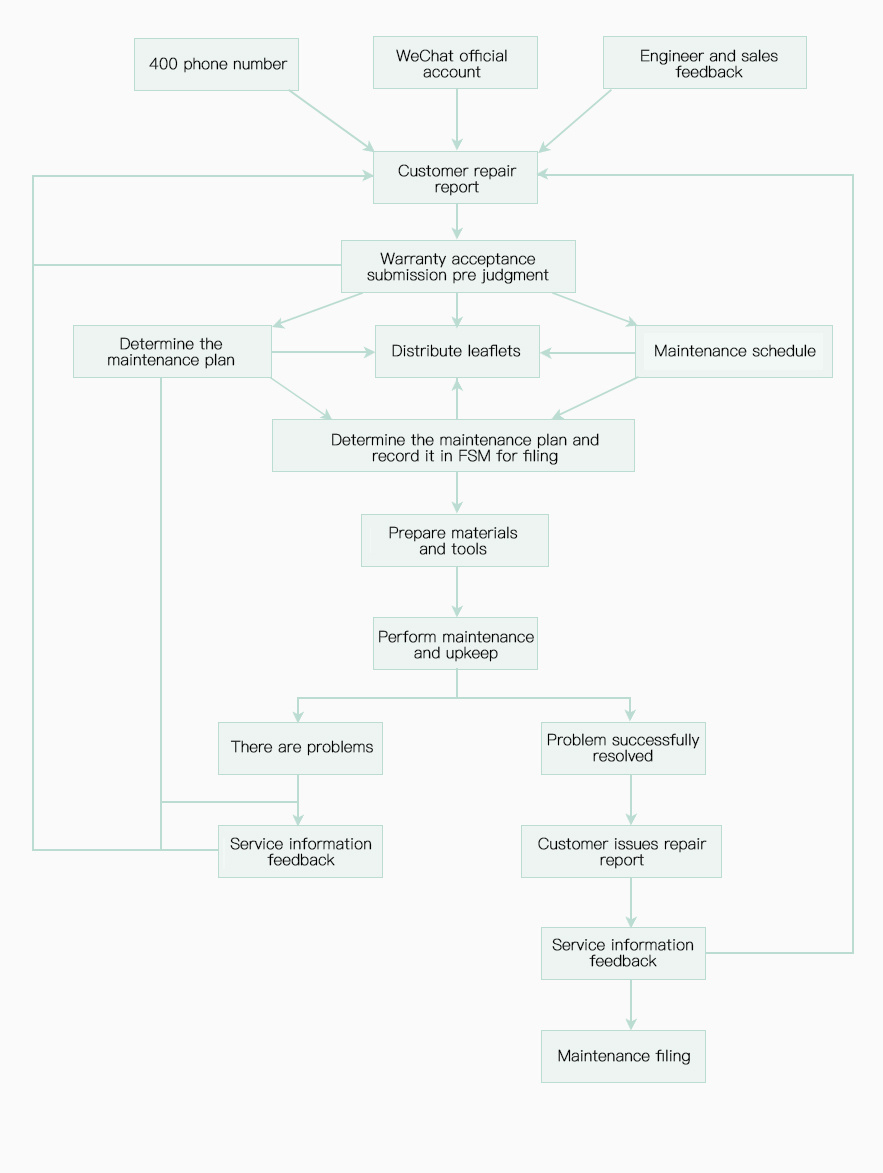

Standardized operation and maintenance process

Immediate Consultation

Please fill in the following information, we will contact you as soon as possible!