Selection and Application of Environmentally Friendly Equipment for Laboratories

Release time:

2025-05-22 13:41

Waste Disposal Plan for Laboratory 01

During experiments, certain toxic and harmful gases, wastewater, and solid waste will be generated. To avoid affecting the surrounding environment, targeted strategies are needed to address this issue.

1. Solid Waste Disposal Plan

Laboratory solid waste includes toxic solid waste, non-toxic solid waste, and sharp waste.

(1) Toxic Solid Waste Disposal Plan

Toxic solids mainly refer to various packaging of toxic reagents, reagent bottles, and all items that have come into contact with toxic reagents, such as containers, gels, and gloves.

Toxic solid waste is stored in dedicated sealed containers, temporarily stored in the waste storage room, and regularly disposed of by qualified units.

(2) Non-toxic Solid Waste Disposal Plan

Non-toxic solid waste refers to general waste and harmless waste generated during experiments, such as waste paper and gloves, as well as laboratory waste that can be safely discarded after disinfection and sterilization.

Harmless solid waste is stored in designated trash cans, collected regularly by designated personnel and transported to the temporary waste storage point, and then uniformly transported and processed by the municipal sanitation department.

(3) Sharp Waste and Toxic Solid Waste

Sharp waste refers to various broken and discarded glassware.

Sharp waste is stored in dedicated sealed containers, temporarily stored in the waste storage room, and regularly disposed of by qualified units.

2. Wastewater Disposal Plan

1) Types of Laboratory Wastewater

Laboratory wastewater includes regular experimental residual wastewater, laboratory equipment cleaning water, and laboratory cleaning water.

Regular high-concentration residual wastewater from experiments is poured into a wastewater bucket. The liquid from rinsing containers 2-3 times should also be poured into the wastewater bucket. Wastewater buckets are stored in the wastewater storage room, and overall room ventilation is provided.

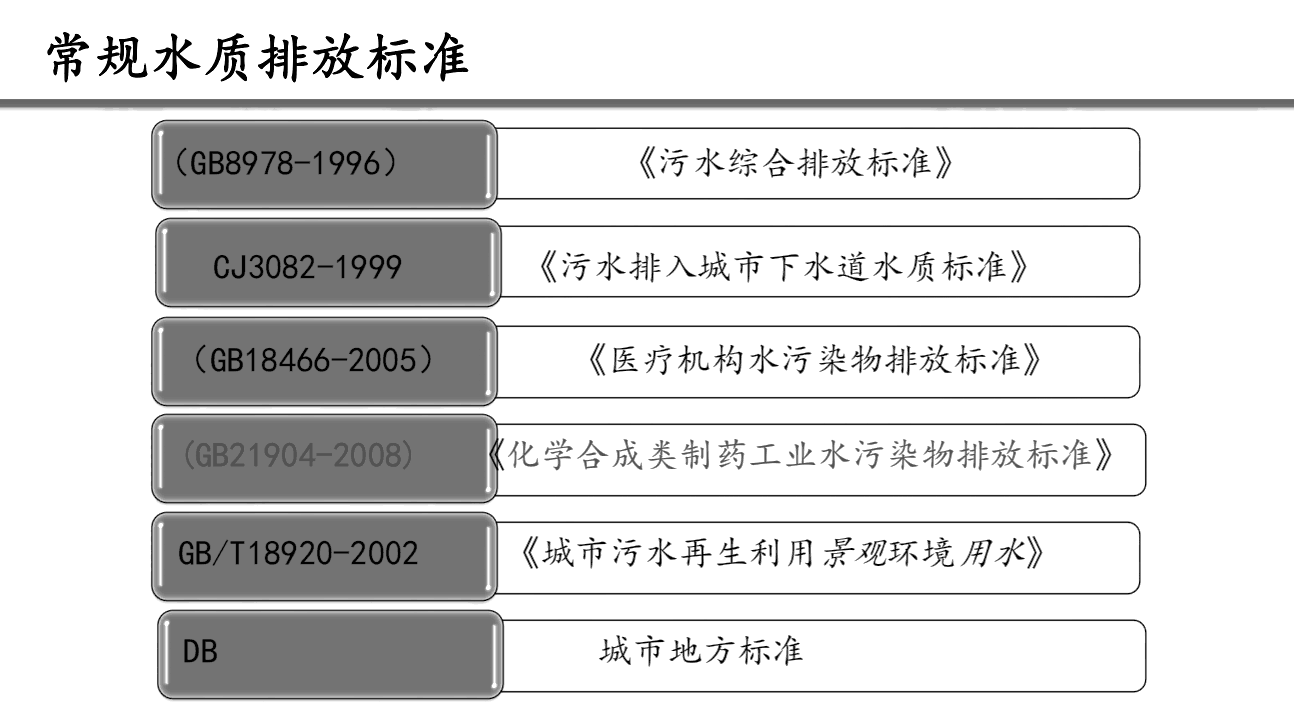

2) Treatment Process

Drainage is designed according to the principle of "separation of clean and dirty water, separation of rainwater and sewage," and wastewater classification collection and differentiated pretreatment measures are implemented. Domestic sewage, pure water preparation wastewater, and backwash wastewater are directly connected to the municipal sewage pipe network. Wastewater from animal cages and animal urine are first pretreated in a septic tank before being mixed with experimental wastewater and laboratory equipment cleaning wastewater and then undergoing advanced treatment in a wastewater treatment device. After treatment, the wastewater is connected to the municipal sewage pipe network.

3. Waste Gas Treatment

(1) Types of Laboratory Waste Gas

Laboratory waste gas pollutants are numerous and complex in composition. The main air pollutants include two major categories: organic gases and inorganic gases. Organic gases include carbon tetrachloride, methane, ether, ethyl mercaptan, benzene, aldehydes, and various other alkanes, alkenes, and aromatic hydrocarbons. Inorganic gases include various acidic volatile gases (such as hydrogen sulfide, sulfur oxides, nitrogen oxides, nitric acid, hydrogen chloride, hydrogen fluoride), and alkaline volatile gases (such as ammonia water, amines). These gases, if directly released into the atmosphere, will directly harm human health and exacerbate acid rain, polluting the atmospheric environment.

(2) Waste Gas Treatment Plan

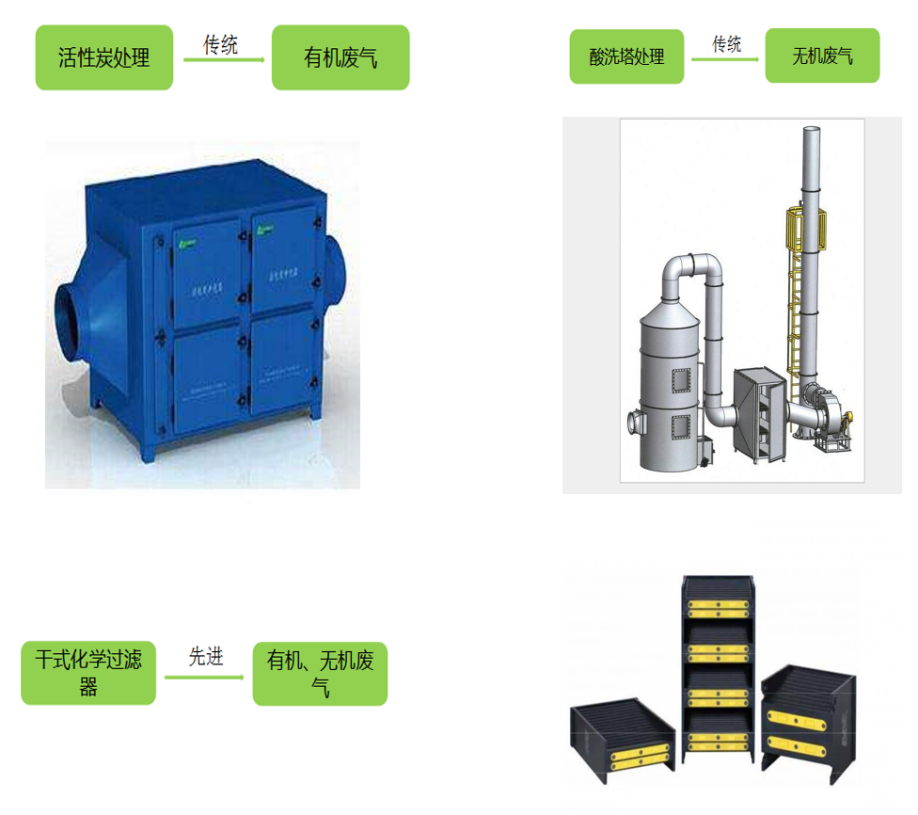

For this type of exhaust gas, activated carbon adsorption devices, acid washing spray towers, and dry chemical filters can be used. Wet filtration systems are commonly used in the domestic market, with representative products being spray towers and scrubbing towers. Dry filtration systems are named in contrast to wet filtration systems, with representative products being dry chemical filters. There are also some exhaust gas treatment devices that use high-energy ions or nano-semiconductor photocatalysis to remove target pollutants. In addition, some biosafety laboratories also use high-efficiency filtration exhaust to ensure that the emitted gases meet environmental or biosafety requirements.

① Activated Carbon Adsorption Device

The activated carbon adsorption device mainly consists of an activated carbon layer and a support layer. Activated carbon has developed pores, a large specific surface area, high adsorption capacity, and high efficiency, mainly for the treatment of organic waste gas.

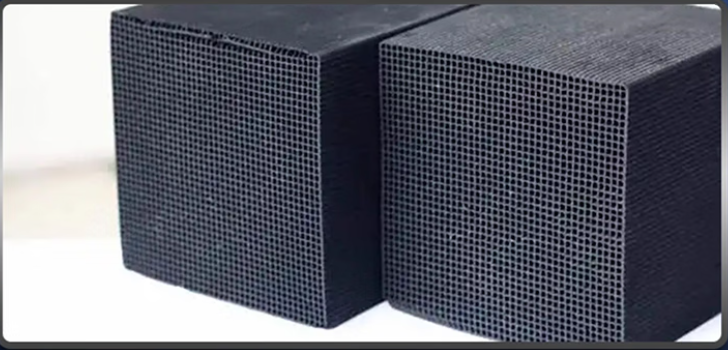

② Dry Chemical Filter

A dry chemical filter is an industrial air purification device based on chemical adsorption and absorption, combining multi-stage physical adsorption and chemical oxidation absorption technology. Using a chemical adsorbent as the filter medium, it performs deep purification of chemical gaseous pollutants and volatile organic compounds in the air. It can effectively treat organic and inorganic waste gases.

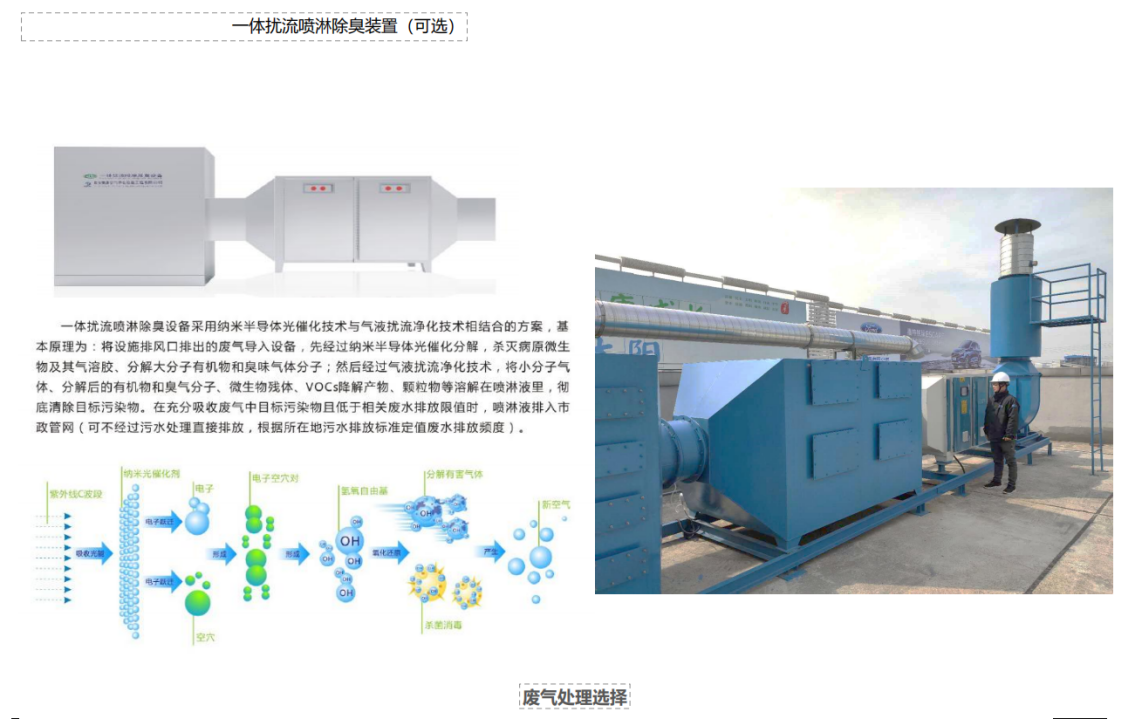

③ Integrated Turbulent Spray Deodorization Device

The integrated turbulent spray deodorization device uses nano-semiconductor photocatalysis technology to break down the molecular bonds in organic and inorganic substances, and then uses gas-liquid turbulent purification technology to transfer air pollutants such as ammonia and hydrogen sulfide from the gas phase to the liquid phase, thereby achieving the purpose of purifying the air.

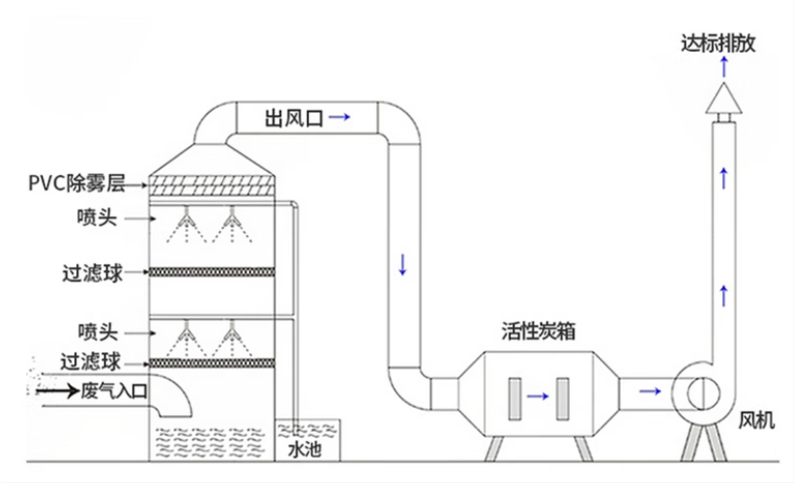

④ Spray Tower

Using the principle of like dissolves like and neutralization reactions, acidic or alkaline solutions are sprayed onto chemical gases passing through the system's interior, causing a chemical neutralization reaction to filter chemical gases, transferring waste gas pollutants from the gas phase to the liquid phase, or further reacting and absorbing them.

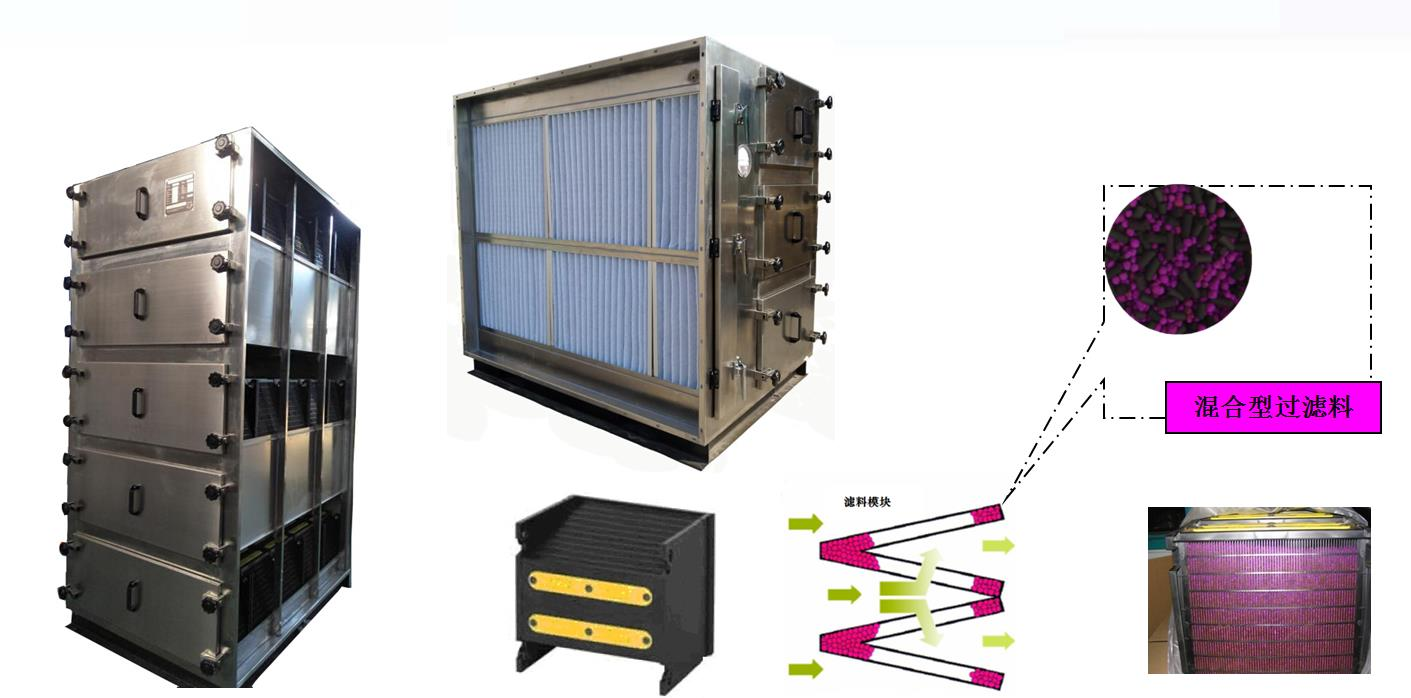

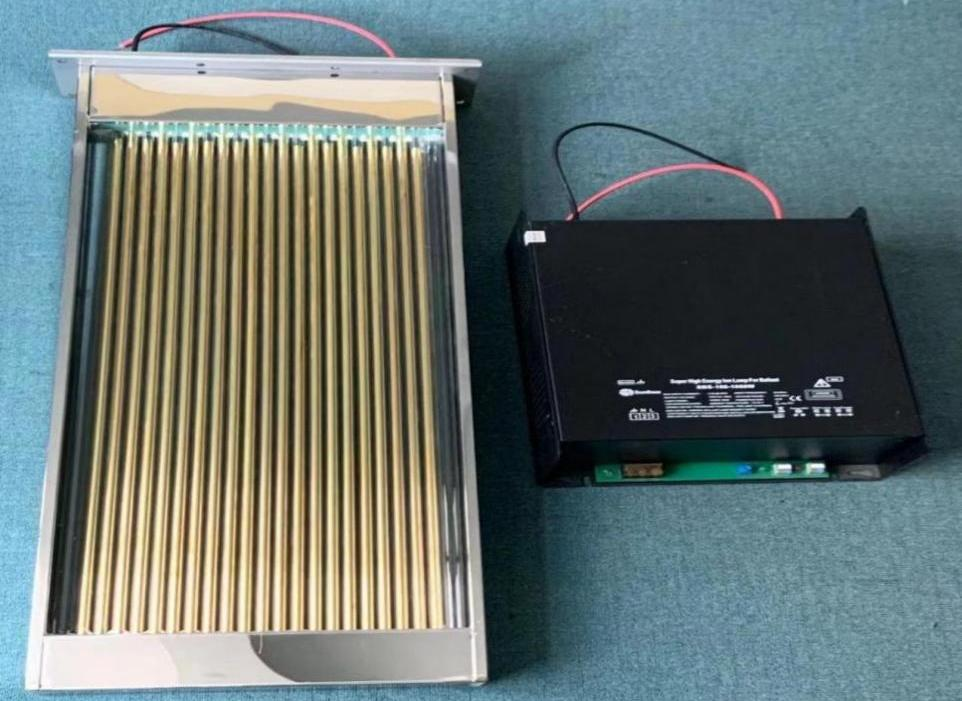

⑤ Compound Dual-Medium Discharge High-Energy Ion Deodorization Equipment

The exhaust gas treatment combination process is: activated carbon + dust filtration + DDBD dielectric barrier discharge + high-energy ions + degradation mixing box.

Dust filtration uses two-stage filters: the primary filter is a stainless steel demister, using a stepped three-stage arrangement to increase the surface area and make it easy to clean; the secondary filter uses a mixed woven mesh, which has higher filtration accuracy and uniform air distribution.

DDBD dielectric barrier discharge technology is a method of obtaining low-temperature plasma at high pressure, generated between two electrodes. Electrons in the dielectric material gain the necessary energy in the electromagnetic field, blocking the discharge and colliding with pollutants. This excites their energy, converting it into internal or kinetic energy. The excited molecules form active groups under the action of ionization, along with water and oxygen, producing new active groups such as ecological hydrogen, thereby triggering a series of chemical reactions.

The high-energy plasma generated activates, ionizes, and cracks various components in the waste gas, causing a series of complex chemical reactions that convert harmful substances into clean, harmless substances that meet the standards for discharge into nature.

It can effectively treat various volatile organic compounds and acid-base gases in exhaust air.

⑥ High-efficiency filter

The high-efficiency filter consists of a sealed frame and a filter unit. Particles >1 μm in size (such as pollen and coarse dust) are directly intercepted by the fiber mesh. Particles ≥0.5 μm are intercepted by inertial impaction on the fiber surface when the airflow changes direction. Tiny particles (<0.1 μm) randomly diffuse to the fiber surface and are captured. Some charged fibers adsorb charged particles. Particles are retained through a combination of multiple mechanisms, purifying the air.

Depending on the different types of waste gas generated in the laboratory, the selection of the corresponding tail gas treatment device is also different. The treatment methods are as follows:

▪ Organic waste gas treatment can use activated carbon devices, dry chemical filters, and composite double-dielectric discharge high-energy ion deodorization equipment.

▪ Inorganic waste gas and mixed organic and inorganic waste gas are treated using dry chemical filters, spray towers, spray towers + activated carbon devices, and composite double-dielectric discharge high-energy ion deodorization equipment.

▪ Animal room exhaust gas treatment can use an integrated turbulent spray deodorization device.

▪ High-efficiency filters can be used in biosafety level 2 and below laboratories.

02

Laboratory Environmental Equipment Selection and Design

1. Wastewater treatment equipment selection and design:

Laboratory water is discharged according to its type. Unpolluted water can be discharged directly. Polluted water is treated and can be discharged into the building's wastewater treatment system if it meets local environmental protection requirements. The design scheme is as follows:

1) Design of inlet and outlet water quality

Ordinary laboratory wastewater has a high concentration of organic matter and good biodegradability. The effluent water quality meets the Class A standard of GB18918-2002, "Discharge Standard of Pollutants for Urban Sewage Treatment Plants," where COD≤50.00mg/L.

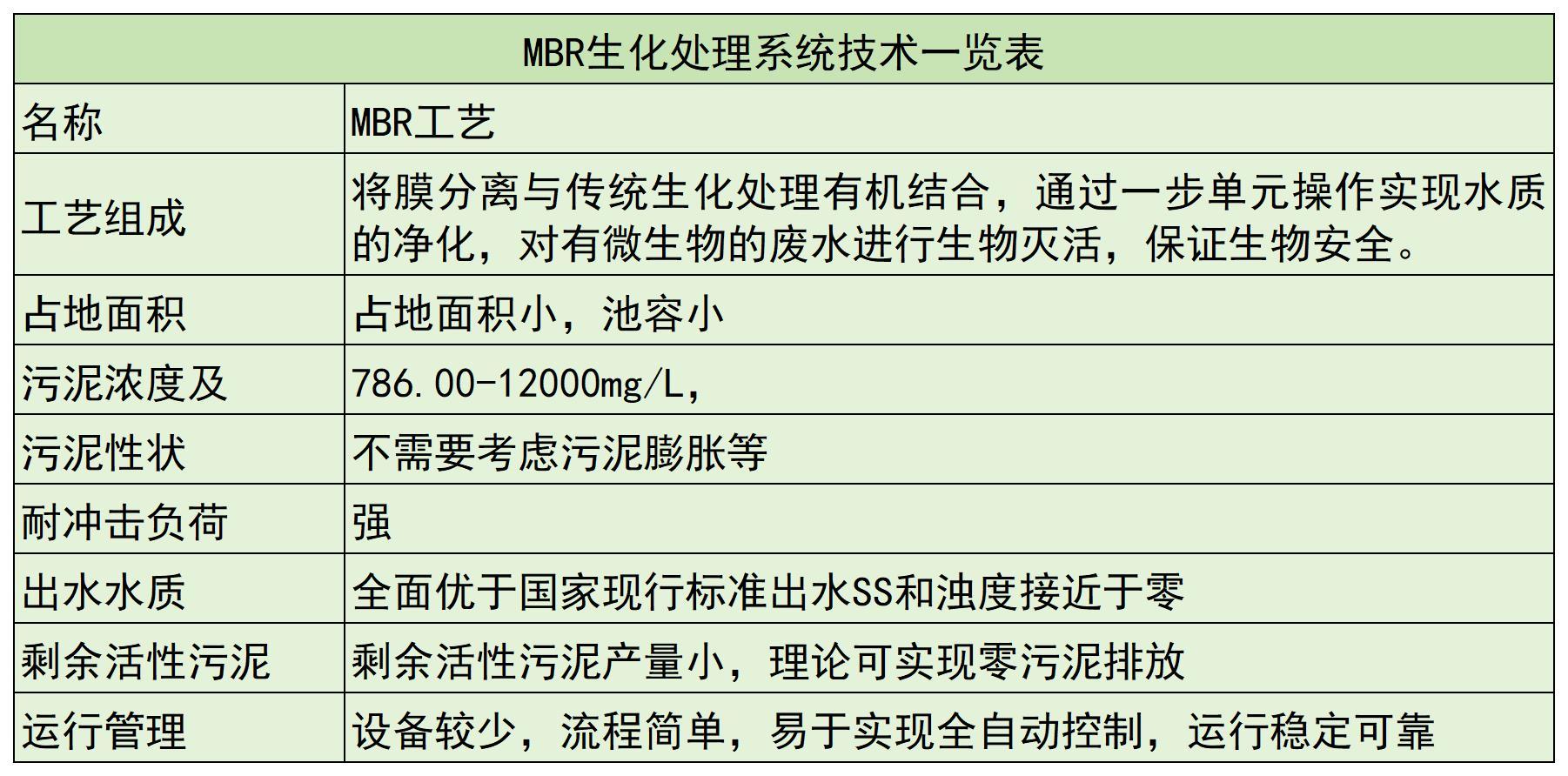

2) Using a flat membrane-membrane bioreactor integrated device

The wastewater mainly consists of microbial water, acidic and alkaline wastewater, and a small amount of organic wastewater, with low organic matter content. After being collected, the wastewater is lifted into an acid-base adjustment tank for pH adjustment to meet the requirements of biological treatment. After pH adjustment, the wastewater enters the subsequent hydrolysis tank and MBR biological treatment system, where the organic matter in the wastewater is completely degraded.

MBR Bio-treatment System Technology Overview

2. Waste gas treatment equipment selection and design:

Laboratory exhaust should ensure that the room is odorless. Waste gas treatment should meet local environmental assessment requirements.

Waste gas treatment: Laboratory testing will produce process waste gas. Direct discharge will pollute the atmosphere. The design treats the waste gas produced by the laboratory process so that the final discharge meets the "Comprehensive Emission Standard for Air Pollutants" and the "Emission Standard for Malodorous Pollutants".

Principles for selecting tail gas treatment:

Activated carbon:

Advantages: Activated carbon has a wide range of applications, is inexpensive, and has a significant effect within a certain range. It can adsorb a certain amount of pollutants in a short time and is very effective in treating organic matter and odors;

Disadvantages: Ineffective for inorganic waste gas treatment. Conventional activated carbon adsorption devices have low initial investment but high actual operation and maintenance costs, are difficult to manage, and their technical applicability is affected by many factors, making it difficult to ensure that tail gas emissions consistently meet standards; unsuitable for dusty waste gas, waste gas containing water vapor or particulate matter. A large amount of activated carbon is needed to treat waste gas. The subsequent treatment of saturated activated carbon is difficult, it only transfers pollutants, does not decompose them, easily causes secondary pollution, cannot form a closed-loop environmental protection system for waste removal, and poses environmental responsibility risks;

Acid washing tower:

Advantages: Very high filtration rate for inorganic waste gas, can handle high-concentration waste gas, and can simultaneously remove acidic gases + particulate matter + some VOCs by adjusting the absorbent, low energy consumption, long maintenance cycle;

Disadvantages: Ineffective for organic waste gas treatment, large footprint, spray tower requires electromechanical equipment, difficult to replace and maintain, spray tower is large and heavy, not conducive to engineering installation in laboratories and research institutions, spray towers are generally suitable for large-scale industrial high-concentration emissions and are of value as pre-treatment. However, laboratory emissions are low in concentration, making it difficult to achieve good filtration of low-concentration waste gas, and wastewater will be produced;

Dry chemical filter:

Advantages: High filtration rate for both organic and inorganic waste gases, absorption efficiency can reach over 90.00%, the dry filtration system can be connected to any suitable position in the exhaust pipe, simple maintenance, no auxiliary power required, filter material can be replaced regularly to ensure effectiveness;

Disadvantages: Currently, the price is slightly higher than activated carbon and acid washing towers;

Integrated turbulent spray deodorization equipment:

Advantages:

1. Best treatment effect, can meet the emission limits of the latest and strictest "Emission Standard for Malodorous Pollutants" 2019 (draft for comments)

2. Low power, energy-saving, no consumables, extremely low operating cost.

3. Small size, light weight, suitable for various new and old facilities.

4. Has multiple experimental animal facility qualified third-party test reports to verify accurate results.

5. Automated operation: unattended operation, remote control, data remote feedback to the monitoring room function.

6. Good applicability and stability, with over 300 experimental animal achievements nationwide

7. It can handle both organic and inorganic substances.

Disadvantages: Patented product, higher initial investment cost, but extremely low later operation and maintenance cost.

Compound dual-medium discharge high-energy ion odor removal equipment:

Advantages: The high-energy ion waste gas odor treatment system has a significant odor removal effect, low cost, low energy consumption, low operating costs, no secondary pollution. It handles organized fixed pollution source waste gas generated by the laboratory. Installed at the end of the exhaust pipe, it can effectively handle various inorganic gaseous pollutants in the exhaust air, effectively improving the pollution of laboratory exhaust gas to the atmospheric environment, and can avoid the risks associated with the emission of biosafety gases;

Disadvantages: Higher initial investment cost, but low later operation and maintenance cost.

Related News