Laboratory Renovation and Reconstruction丨Suzhou Bionic Materials Science and Engineering Center

Release time:

2025-03-25 13:34

The Suzhou Bionic Materials Science and Engineering Center was jointly established in 2021 by the Suzhou Municipal Government and the Suzhou Institute of Advanced Technology, University of Science and Technology of China. The center focuses on the industrial application research of bionic interface science based on original innovation, aiming to serve major national needs, focusing on major fields such as advanced manufacturing, new energy, new materials and biomedicine. It strengthens strategic goal orientation, focusing on cutting-edge leading, common key, modern engineering and disruptive technology research and development and engineering demonstration, striving to enhance independent innovation and engineering research capabilities, making major breakthroughs in strategic key areas and "stuck neck" technologies, constructing a new independent and joint innovation system of "government promotion, targeted teaching, scientific research innovation, technology transformation, financial assistance and industrial landing", breaking through institutional and mechanism constraints that restrict innovation development, building an industrial technology research center aimed at achieving technology transfer, and striving to become an important component of the Yangtze River Delta Innovation Center, a high-level research base with international influence, and a future industrial technology innovation and leading demonstration center.

△The project is located in the world's largest integrated community for nanotechnology applications

Suzhou Nano City

Project Location | Suzhou

Renovated Area | 3932 ㎡

Project Year | 2023

Contractor | Nanjing Expansion Technology Co., Ltd.

The DK20110016 plot (Bionic Materials Science and Engineering) CN28 laboratory project, constructed by Nanjing Expansion Technology Co., Ltd., mainly focuses on the research of polymer bionic materials science and engineering. The first floor is mainly a pilot purification workshop for membrane material molecular manufacturing, the second to fourth floors are mainly related assembly laboratories and material performance testing and evaluation experimental areas and reserved areas, and the fifth floor is a microbial quality inspection-related laboratory and a special process high-precision material production workshop. Nanjing Expansion Technology will renovate the interior.

With professional spirit and rigorous attitude, our company has developed a series of comprehensive optimization solutions for this project. These cover the five-story pilot area, HVAC system optimization of the enzyme crosslinking coating room, upgrade of room pressure difference and automatic control of ultraviolet lamps in the fifth-floor purification area, optimization of the air supply and exhaust fan units on the third and fourth floors and the HVAC system in the first-floor clean area. It also involves energy management system efficiency improvement, optimization of laboratory drainage pipes, and replacement of wall and ceiling color steel plates. The aim is to create a more scientific, efficient and safe research environment for the laboratory, effectively promoting the high-quality development of relevant scientific research work.

△ Electrical Assembly Laboratory

01

HVAC System Optimization Scheme

The HVAC system optimization of this project covers the five-story pilot area, the enzyme crosslinking coating room, the air supply and exhaust fan units on the third and fourth floors, and the clean area on the first floor.

Before the renovation, the five-story pilot workshop used a pre-cooling section + rotary dehumidification mode. However, rotary dehumidification has the drawback of huge energy consumption, which is not conducive to long-term cost control. In response, our company has proposed a highly targeted optimization scheme: to independently equip the pilot workshop air conditioning system with a low-temperature chilled water air conditioning system (2°C outlet water). Considering the relatively large reheating amount, it is recommended to use a four-pipe air conditioning system to achieve effective cooling and dehumidification, precisely controlling the indoor temperature and humidity to 25℃, 35-40%. After this optimization, the pre-cooling section and rotary section can be directly canceled. This measure can significantly reduce operating energy consumption. According to calculations, the rotary section equipment in this project usually has a power of 60-70 kilowatts during operation in summer and transitional seasons. After cancellation, the energy-saving effect is very significant, and an estimated annual energy cost savings of 100,000 yuan can be achieved, and 100,000 yuan can be saved in initial investment. While ensuring functional requirements, comprehensive cost control and resource optimization are achieved.

△ Film-making Laboratory

As a low-humidity laboratory with high humidity precision requirements (adjustable), the enzyme crosslinking coating room has strict requirements for the temperature fluctuation of the cold and heat sources, with a conventional precision of ±0.2°C, and also requires year-round stable cold and heat supply functions. However, the building's cold and heat sources before the renovation could not meet this standard. After in-depth research and planning, our company suggests using a variable frequency unit with a four-pipe air conditioner and setting a buffer water tank. By adding a plate exchanger, the cold and hot water fluctuation is further guaranteed, ensuring that the cold and hot water temperature fluctuation is controlled within ±0.2°C. In terms of humidity design, it is meticulously crafted to ±1%, and the temperature is ±0.05°C, using an electric heating humidifier and configuring a hot water tank. Through thyristor linear regulation and pure water supply, precise humidification is achieved. In addition, the rotary dehumidification technology with a heat recovery system is used to effectively improve the energy-saving effect. In terms of coil design, it covers pre-cooling, primary surface cooling, secondary surface cooling, reheating coils, and end SSR temperature control links, comprehensively ensuring that the temperature and humidity fluctuation is always within the precise range of design requirements. From equipment selection to system design, every step fully considers the special needs of the laboratory to maximize the guarantee of smooth experiment progress and reduce operating costs.

△ Coating Room

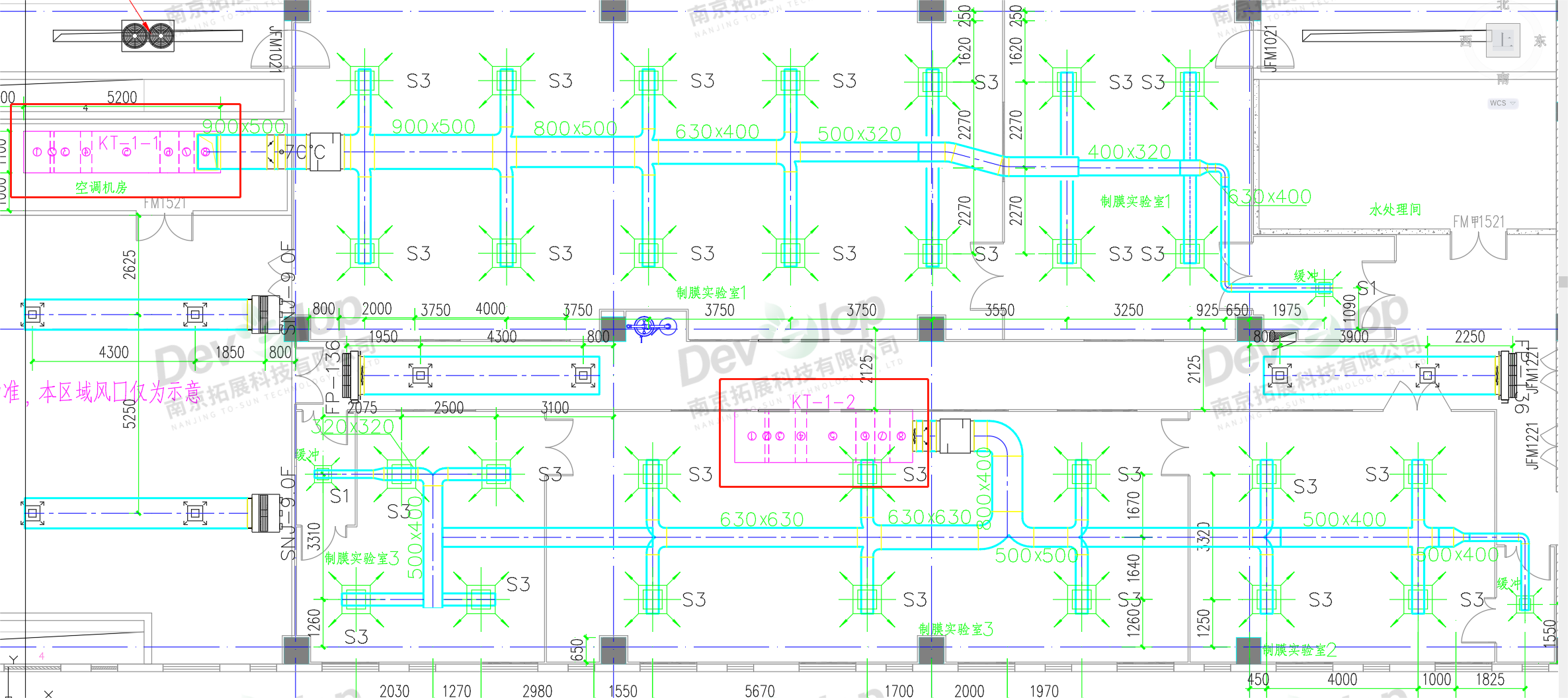

The first-floor film-making laboratory is currently divided into five air conditioning systems, which increases the cost of main equipment, water system valves, and self-control, as well as maintenance costs in the future. It can be merged into two north-south air conditioning systems to provide sufficient air volume to the original JK-1-1, JK-1-2, and JK-1-3 air conditioning areas, ensuring temperature and humidity requirements. At the same time, the heat dissipation in the JK-1-1, JK-1-2, and JK-1-3 air conditioning areas is relatively large, which can be optimized to be a year-round cooling condition. After optimization, the engineering cost can be reduced, maintenance costs can be reduced, and the failure rate can be reduced.

△ Optimized as shown

02

Self-control System Optimization Scheme

Currently, the pressure difference control of the fifth-floor laboratory relies on the adjustment of interlayer manual valves, which has problems such as lagging adjustment and easy disorder, and requires long-term maintenance by professional personnel. To ensure the stability of the pressure difference gradient, it is recommended to add a variable air volume electric control valve on the basis of the existing pressure difference monitoring system and connect it to the self-control system to achieve dynamic control. By real-time monitoring of the pressure difference data in each area, the system automatically adjusts the valve opening to ensure that the pressure difference gradient between the buffer zone, core area and equipment room meets the design requirements, reduces manual intervention, and improves control accuracy and reliability.

△ Assembly Laboratory

The ultraviolet lamps in the fifth-floor laboratory are currently controlled by on-site manual switches, which poses a risk of misoperation and lacks a disinfection status reminder. The optimization scheme will connect the ultraviolet lamp control to the self-control system, and configure a dedicated touch screen at the laboratory entrance to achieve centralized start-stop control and status monitoring. The system adds the following functions:

·Access Management:Avoid accidental triggering through hierarchical operating permissions (such as administrator, operator);

·Disinfection Warning:After the ultraviolet lamp is started, the touch screen image will flash in real time to warn personnel not to enter;

·Operation Traceability:Record disinfection time, operators, and other data for audit management.

03

Air Supply and Exhaust Fan Unit Optimization Scheme

Regarding the optimization scheme for the three-layer and four-layer fresh air exhaust system, professional calculations show that the originally designed heat recovery type air supply and exhaust unit is too expensive. To effectively control construction costs, our company suggests replacing the integrated unit with a split-type heat exchanger + exhaust fan + air conditioning unit combination system. This optimization scheme, while fully realizing the original ventilation and heat recovery functions, can reduce procurement costs by nearly 200,000 yuan through equipment selection and reorganization, without affecting system operating efficiency. The split-type solution meets technical specifications and significantly improves project economics.

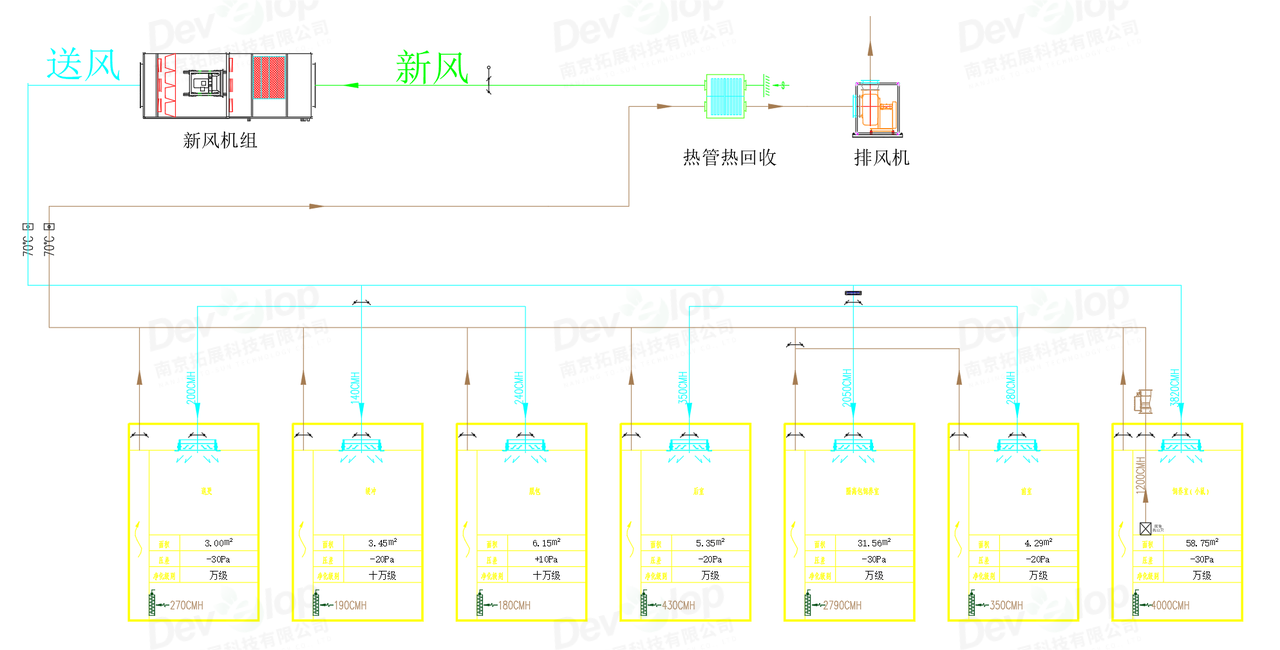

△ Optimized air handling process

04

Energy Management System Optimization Scheme

For the laboratory power metering system, it is recommended to integrate and restructure the originally designed, dispersedly configured multifunctional electricity meters with the energy management system. By Canceling redundant energy meters, flow meters, and laboratory itemized electricity meters, and using a "total-sub" power distribution monitoring architecture, we can achieve refined management of floor power consumption and significantly reduce equipment procurement and maintenance costs. According to calculations, after adopting a hierarchical and zonal centralized metering model, the number of electricity meters in the entire building can be reduced by about 40%, saving an estimated 300,000 yuan in cost, while still meeting the core needs of independent monitoring of key equipment power consumption, overall laboratory energy consumption statistics, and HVAC system special metering.

△ Testing Room

The specific implementation plan is as follows: The first-floor production workshop will use a total distribution box meter according to equipment cluster configuration, and the laboratory HVAC will have an independent total meter; the second to fourth-floor laboratories will Cancel individual electricity meters and use a dual metering system of the laboratory total distribution box + air conditioning total box per floor; the fifth floor will use a combination of production workshop itemized metering and overall laboratory metering, while separately monitoring air conditioning power consumption. This scheme, through an integrated design that combines individual elements into a whole, significantly reduces initial equipment investment and later line maintenance complexity while ensuring the completeness of key data acquisition, systematically improving project economics.

In addition, we have also optimized the laboratory drainage pipes, wall and ceiling color steel plate materials. While meeting the laboratory performance requirements, this significantly reduces costs and achieves high cost-effectiveness.

△ Renderings

△ Renderings

Related News