Control of Large Space Constant Temperature and Humidity Clean Experimental Environment at the Nanjing Institute of Astronomical Optics and Technology, Chinese Academy of Sciences.

Release time:

2025-02-18 15:46

Nanjing Institute of Astronomical Optics Technology, Chinese Academy of SciencesThe construction site is located in Qilin Science and Technology Innovation Park, NanjingA3Land4In Building No., this experimental environment guarantee project is constructed for the research institute"13th Five-Year Plan"The project of supporting the astronomical optical technology experimental and large-caliber astronomical telescope testing and adjustment guarantee platform is a necessary supplement to the experimental environment conditions of the astronomical optical technology experiment and large-caliber astronomical telescope testing and adjustment guarantee platform project.

The full realization of all scientific research functions of this guarantee platform will play an important role in the innovative research and experimental development of key core technologies for these major national tasks.

△Project location map

Project location | Nanjing

Project area |7999 ㎡

Project year |2024Year

01

High and spacious constant temperature and humidity clean experimental environment control

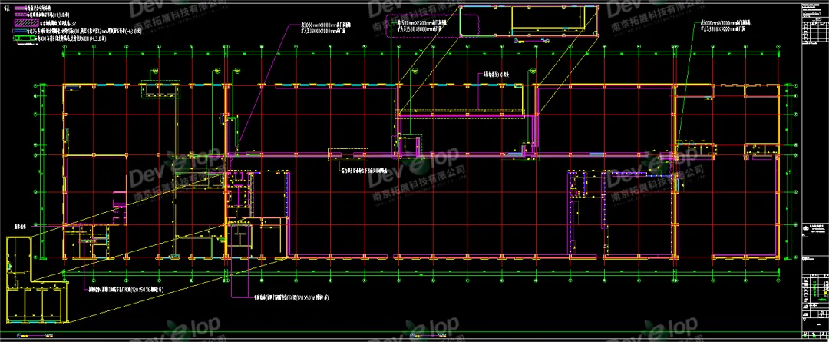

The total area of this project is7999m², including the fine grinding and polishing area in the astronomical optical technology experimental platform2370㎡, precision measurement and interference testing area554㎡, large-caliber ring grinding714㎡, adjustment and testing platform's adjustment and vertical inspection area575㎡, coating operation area318㎡.The maximum usable height reaches11meters(the highest color steel plate ceiling is12.5meters). This project is aimed at secondary decoration of the above corresponding experimental areas, with the main construction content including decoration of the ground, walls, and ceiling, as well as in-depth design and installation of water, electricity, heating, ventilation, and intelligence.High and spacious constant temperature and humidity clean experimental environment control.

△Project layout map

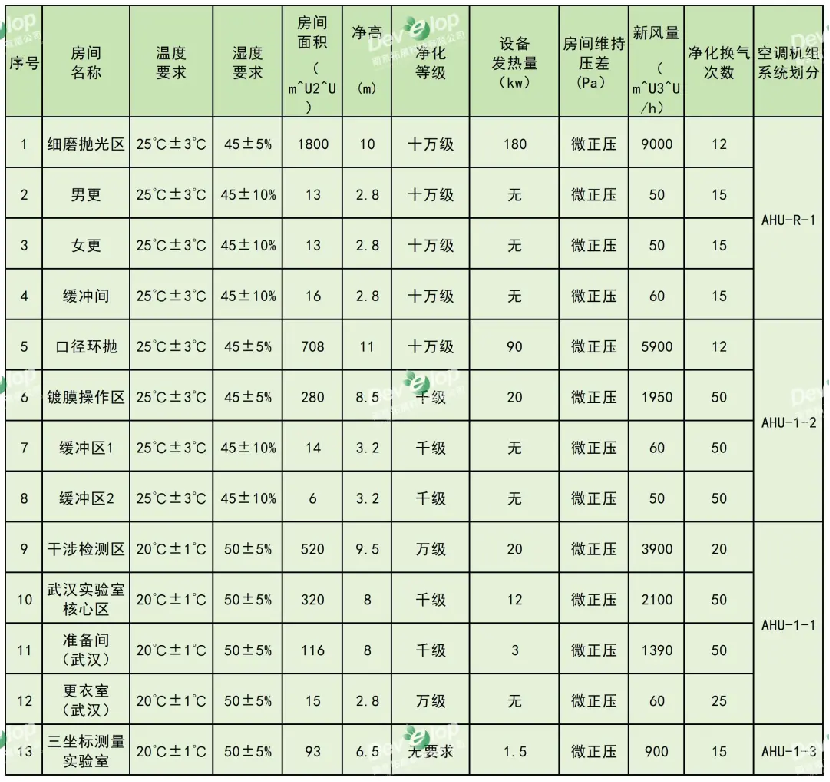

Due to the height of the space reaching 11meters, the natural convection phenomenon of air is obvious, and the heat and humidity can easily produce large differences at different height levels, making it extremely difficult to control the uniform distribution of temperature and humidity. Moreover, the large volume of the high space requires high cooling and heating capacity and humidity adjustment capability of the HVAC system to achieve constant temperature and humidity throughout the entire space..At the same time, to maintain a clean experimental environment, it is necessary not only to prevent the intrusion of external pollutants but also to effectively control the diffusion of tiny particles and harmful gases generated during internal experiments, which requires the installation ofan efficient air purification system and strict airflow organization design, to ensure that the experimental environment always meets stringent cleanliness standards.

△Project response technical requirements

02

Customized for different areasdifferentiated HVAC system technical solutions

The experimental environment has a crucial impact on the accuracy and reliability of various experiments, especially in this project, different experimental areas undertake different key tasks, and the requirements for the air environment vary accordingly. For the fine grinding and polishing area, it is easy to generate fine particles and dust during the precise grinding and polishing of materials, and it is sensitive to changes in temperature and humidity; any deviation may affect the precision and quality of polishing; the large-caliber ring grinding area, due to the large size of the workpieces being processed, has extremely high requirements for air cleanliness and airflow stability to ensure uniformity and consistency in the grinding process; the coating operation area requires a highly clean environment to prevent impurity particles from adhering to the coating surface, affecting the performance and quality of the coating; the ultra-clean integrated laboratory, as the core area for high-precision experiments and research, has almost harsh requirements for aircleanliness,temperature and humidityandairflow organization.……

Based on the special needs of the above areas, forfine grinding and polishing area, large-caliber ring grinding, coating operation area, ultra-clean integrated laboratory, interference testing area,GTCassembly laboratoryThese areas with extremely high requirements for air cleanliness and temperature and humidity control will adopt a combined air conditioning box dehumidification treatment+ FFU(fan filter unit)+DC(dry cooling coil) comprehensive approach. FFUs are evenly distributed at the top of the clean area, fully utilizing a large amount of circulating air to maintain the stability and cleanliness of indoor air. The treated primary air (mixed from fresh air and return air) first fully mixes with circulating air in the return air duct, and then is further processed by the dry cooling coil set in the ceiling before entering the upper return air static pressure box. Next, the airflow ispressurized and efficiently filtered before being sent indoors. The indoor return air is then returned to the return air duct through the return air louver at the lower side of the side wall, completing the entire airflow cycle. The specific airflow process is: return air, fully utilizing a large amount of circulating air to maintain the stability and cleanliness of indoor air. The treated primary air (mixed from fresh air and return air) first fully mixes with circulating air in the return air duct, and then is further processed by the dry cooling coil set in the ceiling before entering the upper return air static pressure box. Next, the airflow is→mixed with primary airdry cooling coil (mixed with primary airDC))→FFU→Laboratorymixed with primary airLower return air grille on the side wallmixed with primary airReturn air corridor.

△Fine grinding and polishing area

In view ofCoordinate measuring laboratorythe detection accuracy requirements, the airflow organization form of upper supply and lower return is adopted. Through double-layer louver air supply outlets, static pressure layers, and micro-perforated aluminum plate top air supply, it ensures that the air entering the room is uniform and stable. The return air is achieved through the side return air method set at the lower part of the return air column, realizing effective circulation of indoor air to meet the strict requirements of coordinate measurement for environmental airflow.

△Coordinate measuring machine room

This differentiated design scheme not only meets the strict requirements of each area for air cleanliness, temperature and humidity, and airflow stability, providing a solid guarantee for the smooth progress of experiments and the normal operation of equipment, but also improves energy utilization efficiency to a certain extent, reduces operating costs, and reflects the design concept of being green, energy-saving, and efficient.

03

Laboratory temperature and humidityControl system technical plan

The temperature and humidity automatic control system of this project adopts popular and mature technical standards both internationally and domestically, using advanced distributed control systems. Through the upper computer software system of the central monitoring layer and the network control layer'sPLCcontroller, it achieves decentralized control and centralized management. From the perspectives of professionalism, advancement, practicality, reliability, energy saving, and convenience, it monitors the air conditioning machine room and the terminal of the experimental environment.

△Assembly and vertical testing area

The automatic control system aims to ensure the safe and stable operation of equipment and improve management efficiency. The operation interface is human-computer interaction, one-click start, easy to operate, fast and stable. Each set of experimental environment air conditioning units is equipped with an independent local control cabinet for easy maintenance and upgrades.Laboratory users and after-sales maintenance personnel can remotely control operations through computer clients or mobileAPPRemote operation and maintenanceExperimental users can remotely manage system equipment'sStart and stop,Parameter settings,Remote power on and off, etc.In case of system faults, our maintenance engineers can also penetrate remote access nodes to performPLCremote online diagnosis, program download updates, and other operations. This can greatly improve the efficiency of system maintenance, save time costs, and allow for immediate online resolution when the system experiences soft faults.

After the automatic control system is put into operation, the maintenance of system equipment faults is the most critical aspect. Many laboratories often incur certain losses due to the failure to promptly detect and repair equipment faults during use.. Therefore, building a WeChat push system is particularly important. Experimental users and our maintenance personnel only need to open WeChat and scan the QR code on the automatic control system control interface to follow the corresponding equipment public account, so that they canreceive WeChat push notifications of equipment fault events at the first moment when equipment operation fails, allowing for timely repair.Example of the push system page.

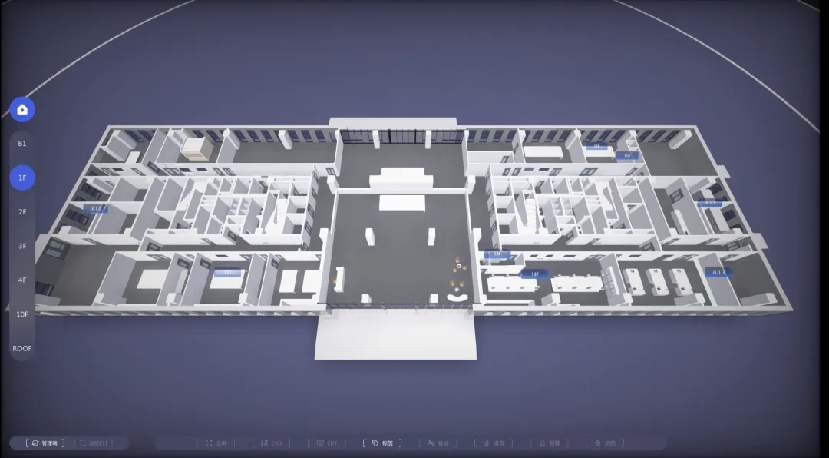

△In addition, the laboratory

Visual operation management platformutilizes the built-inengine to create a vectorized3Ddegree360new interface, supporting arbitrary scaling and rotation of three-dimensional real-time operation and maintenance, achieving equipment instrument operation and maintenance monitoring, scene roaming, fault location, and inspection. The system has an IoT platform suitable for laboratories, connecting various general industrial control sensors to collect3Dlaboratory environment (temperature and humidity, etc.)andequipment operation and maintenance (water, electricity, HVAC, access control, etc.) data, completing transmission, analysis, and statistics, allowing for customizable safety warning rules, thresholds, and alarm recipients, achieving round-the-clock monitoring.Visual operation and maintenance management platform

△uses professional strength to resolve construction challenges in large spaces.

04

During the project implementation process, a series of severe challenges arise from the large space. The special structure of large spaces limits the construction operation area, increasing construction difficulty, while also posing higher risks during construction, potentially threatening the safety of construction personnel. In the face of these difficulties, our company relies on

rich construction experienceandequipment operation and maintenance (water, electricity, HVAC, access control, etc.) dataexcellent technical capabilitiesto implement a series of effective solutions. In terms of equipment selection, we actively introduce professional equipment with high safety, such as articulated boom lifts and diesel-powered lifts. Although such equipment is relatively expensive, it provides a safer and more reliable working platform for construction personnel, effectively reducing construction risks and ensuring smooth construction.

△Project construction site

At the same time, our company places great importance on the management and supervision of the construction process. We arrange professional management personnel to supervise and guide the construction site throughout the process, strictly controlling the construction process according to construction specifications to ensure that every construction link meets standard requirements. For safety protection measures, we conduct strict and detailed inspections daily and supervise construction personnel to ensure compliance, providing institutional guarantees for construction safety. Through these comprehensive measures, we fully demonstrate our company's strong construction capabilities and high safety responsibility awareness in dealing with complex construction environments, providing a solid guarantee for the high-quality completion of the project.

Company Introduction

Nanjing Expansion Technology Co., Ltd. was founded in1999, is a national high-tech enterprise, specializing in the overall planning and design, construction installation, operational support, and scientific research of special experimental environment projects such as constant temperature and humidity, biological safety, clean purification, high-precision control, and laboratory animal facilities. It has been recognized by the Jiangsu Provincial Department of Science and Technology as the Jiangsu Provincial Precision Smart Experimental Environment System Engineering Technology Research Center.

The company has undergoneWith over 20 years of hard work, we have achieved a professional level in laboratory temperature, humidity, and cleanliness control, as well as energy-saving and intelligent application technologies. Our clients are spread across the country and extend overseas, having undertaken over 3000 projects, with our main business covering:Higher education institutions and research organizations, international testing organizations, national testing centers, government-related testing institutions, health care, biopharmaceuticals, national defense science and technology, precision processing, textiles and clothing, paper packaging, materials and chemicals, tobacco, and other industries with numerous experimental needs.The company has won high recognition from clients with advanced technology, strict management, reliable quality, and comprehensive services.

Related News